10 years ago, I wrote about handmade engagement rings. Back then, in times some may say were simpler, jewellers could merely listen to what the client wanted, or prepare a hand drawn sketch before manufacturing a piece of jewellery. During the handmade manufacturing process, seemingly minor details of the design may have been overlooked – attributed to “jewellers discretion”. When finished, the client was presented with the piece of jewellery. Whilst most of the time the client loved the finished product, sometimes the whole piece needed to be remade due to a minor detail. However, as with a lot of things in life, technology is changing how business is done and how products are manufactured and bought. Gone are the days of hand drawn sketches and handmade jewellery. Nowadays, CAD/CAM is what fine jewellery consumers are demanding.

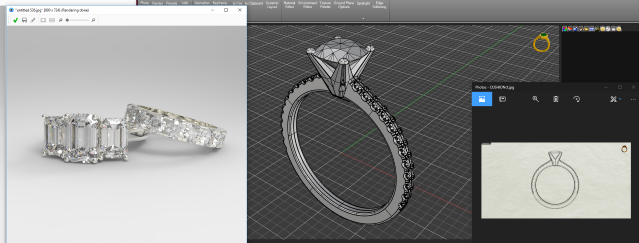

CAD/CAM stands for computer aided design and computer aided manufacturing. This process, when applied to jewellery, means that the piece of jewellery is designed with CAD software and photo realistic renders are sent to the customer for their approval. At this stage, changes can be made to the design until everything is perfect. In addition to this, we even offer a service where we can 3D print a plastic model for our customers to try on. Once the design is approved, the piece of jewellery is 3D printed so a plaster mould can be made and the piece cast in metal. After the piece is cast, it is cleaned up and assembled by a jeweller, the diamonds and gemstones set into the metal and then finally it is polished.

Above: CAD and rendering software

The first benefit with the CAD/CAM process is that the finished piece of jewellery is replicated pretty much 100% from the design. Therefore, there is no room for “jeweller’s discretion” in altering the design during the manufacturing process, and thus no middleman between the designer and the customer. Secondly, the customer is presented with photo realistic renders and even 3D models before manufacture. From my experience, this is a far more engaging process for customers than a simple hand drawn sketch. In fact, most of our customers are demanding designs and renders for their jewellery – even for simple wedding rings!

Now as with any revolution, there will be traditionalists who are vehemently opposed to it. I experienced this from brick and mortar retailers when we first started selling diamonds online, and now have experienced the same thing in respect to CAD/CAM from bench jewellers, even those who I directly employed. The two main arguments from these bench jewellers are:

- CAD/CAM is a cheaper option than handmade. This is simply not true, as the same amount of raw materials are used, and the labour cost is usually about the same. The main difference is the labour cost mostly in the design and preparation, rather than paying someone on the bench.

- CAD/CAM is cast and therefore structurally weaker. This can be de-bunked by offering the same guarantees as a handmade piece. For example, we offer the same warranties and guarantees for our cast pieces as handmade pieces. If it was true, then we wouldn’t offer such guarantees on our cast pieces.

The irony is that bench jewellers who complain about CAD/CAM have 90% of the skills and knowledge required to start designing using CAD – they just need to spend a little bit of time learning software, which many have done.

Jogia Diamonds has been offering CAD/CAM for about seven years now. In that time, we’ve gone from one CAD job per week, to bringing in all our CAD/CAM operations in house, to 50-60% of our clients wanting a custom designed ring using CAD/CAM. Whilst we could have continued handmaking all our jewellery, as we did earlier in the decade, customer demand for CAD/CAM was too much to ignore. This can even be reflected in our staff. When we first started offering CAD/CAM, we outsourced the design and had jewellers in house. Now we do all our design, casting and diamond setting in house, whilst outsourcing the cleaning and assembling to bench jewellers.