To complement the quality diamonds that we sell, we also sell a range of engagement rings, as well as diamond ear studs. For years, we have been hand-making our rings in our Perth workshop, however, due to demand, we will soon we will begin offering cast engagement rings at a lower price.

When buying a ring, most people don’t think twice, nor do they know, about how the ring was manufactured, or how the way it was manufactured affects the quality and other aspects of the ring. The two most popular ways of manufacturing rings nowadays are casting and hand-making the ring.

What is Casting and What is Handmade?

Casting is a process whereby a mould is made in the shape of the piece of jewellery or whatever is being cast. To put it simply (and the process is far more complex), metal is then poured into the mould, which then hardens and the cast is produced. This process is similar to making jelly, and multiple casts are done at once on a “tree”, as shown below:

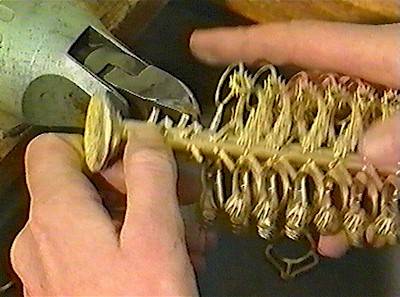

Handmade jewellery refers to a bench jeweller, along with a gemstone setter, and sometimes a specialist polisher, collaborating to make a ring or piece of fine jewellery. Put very simply, the bench jeweller makes the piece of jewellery by melting down gold and shaping it into whatever shape needed, or by “carving” a small strip of metal. The gemstone setter then sets it and the polisher polishes it.

The setter is still needed with a cast ring, but pre-polishing can be done at the casting factory, meaning final polishing will be a lot easier.

Casting Benefits:

- Cheaper, meaning you may be able to buy a bigger diamond or shoulder diamonds. Cast rings also create a lower price point, meaning for price points of around $1500 are available for a small engagement ring.

- The ring you see in a catalogue or online will be exactly the same, as casting produces the same ring every time, unlike a handmade ring which is made by a jeweller.

- 3D CAD models and waxes may be available. This is a lot more life-like than drawings that are usually done in the hand-making process.

- Modern casting techniques are less porous than ever before, meaning the ring will be stronger. Plus, as part of the modern casting process, the person designing the ring can make changes with a click of a mouse and possibly have a wax printed for you to see.

- Less metal wastage, especially when there are channel set diamonds.

Handmade benefits:

- Inherently stronger.

- Easy to make modifications during manufacturing process, such as a narrower band or lower setting.

- Can be made quickly, unlike sending orders to a casting factory which may work on a timetable or be in another city. This is good if you need the ring the next day or next week.

- You will be getting a unique ring – small “imperfections” or changes are intrinsic to the process of handmaking a ring.

- Designs are not limited and you can mix metals. For most designs, a two-piece cast allows for different metals for the setting and band, however some designs like this one can not be cast with say a yellow gold band and white gold setting.

So, which method is best for you?

Well, if you like the idea of a ring that will last for generations, have a unique design or want to alter an existing design, and you don’t mind spending an extra $2-300, then handmade is the way to go.

However, if you want something that is cheap, reasonably durable and looks exactly like something in a catalogue, then casting is the way to go.

May 24th, 2010 at 12:53 am

I have frequented your blog before. The more I read, the more I keep coming back! 🙂

September 11th, 2020 at 4:35 am

Great comparison..thank you!